Pipette tips are disposable plastic cones, designed to fit on pipettes, to transfer a precise volume of liquid.

移液頭是一次性塑料錐體,安裝在移液器上,以轉移精確容量的液體。

?Differentsizes : from 10 μL (? ~3mm * ~30mm) to 1500 μL (? ~10mm * ~100mm)

?Lightweight: Between 0,1g and 1g

?Wall thickness in general 0.3mm

?尺寸:從10μL(?~3mm*~30mm)到1500μL(?~10mm*~100mm)

?重量:0.1g至1g之間

?壁厚一般為0.3mm

Machine technology related/機器技術相關

01

Typical mould sizes (200μl tip)

16cav – IntElect2 S 100 – cycle times 4s+

32cav – IntElect2 S 130 – cycle times 4s+

64cav – IntElect2 S 180 – cycle time 4s+

128cav – El-Exis SP 300 – cycle time 4s+

Injection unit depending on pipette tip design.

Average screw size 45mm with L/D 20 (200μl & 64cav.).

典型模具尺寸(200μl 尖頭)

16腔 – IntElect2 S 100 – 循環時間 4s+

32腔 – IntElect2 S 130 – 循環時間 4s+

64腔 – IntElect2 S 180 – 循環時間 4s+

128腔 – El-Exis SP 300 – 循環時間 4s+

注射單元取決于移液頭的設計。

平均螺桿尺寸 45mm,長徑比 20 (200μl & 64cav.)。

02

Direct drive technology

?Stroke normally low (0.3 to 1D)

?Fast acceleration à Fast injection à No stress to the material ?Low runout tolerance in all cavities

?Fast cycle time

直驅技術

?行程通常較短 (0.3 to 1D)

?快速加速>快速注射> 材料無應力

?所有型腔的公差跳動小

?快速循環時間

03

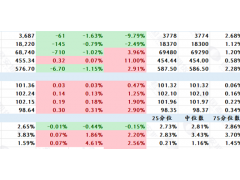

Energy consumption [kW/h]

Typical application for 64cav.tips :

?180t, SC 40mm

?Shot weight 16g

?Cycle 5 sec

能耗 [kW/h]

64腔移液頭的典型應用:

?180t, SC 40mm

?注射重量16克

?周期 5s

IntElect 2 is also up to 80% more efficient than hydraulic machines for pipette tips !/IntElect 2生產移液頭的效率比液壓機高出 80%!

04

Machine layout/機器布局

Our advantages-Services and Comzzpetences/我們的優勢——服務與能力

Risk reduction for our customers

為客戶降低風險

?Selection of partners to support complex applications (Production cells)

?Setup of Traceability Matrix / Change log

?Ergocheck (Calibration of the machine)

?Extended support during FAT/SAT with GMP trained personnel

?選擇合作伙伴以支持復雜的應用(生產單元)

?建立可追溯性矩陣/更改日志

?Ergocheck(機器校準)

?在 FAT/SAT 期間由經過 GMP 培訓的人員提供擴展支持